Determination of granulometric parameters has been a major focus of sedimentary studies and is of growing interest in the Earth sciences. There is a variety of instrumental techniques for the measurement of particle size. These include sieve and pipette methods through laser scattering to image analysis of pictures taken by optical or scanning electron microscopes. These various analytical methods are based on different approaches to measuring particle size.

(For more details: Varga, G. et al. (2018). Granulometric characterization of paleosols in loess series by automated static image analysis. Sedimentary Geology 370, pp. 1-14.)

(For more details: Varga, G. et al. (2018). Granulometric characterization of paleosols in loess series by automated static image analysis. Sedimentary Geology 370, pp. 1-14.)

Introduction

Grain size characterization of irregular shaped three-dimensional sedimentary particles is a complex problem. The size of such particles is approximated by using equivalent diameters, so that the real irregular particle is replaced with an imaginary sphere or circle having similar volume, surface or area. This means that sphere equivalent (SE) or circle equivalent (CE) diameters are used instead of other size parameters. However, size description of a non-spherical particle using simple indices (SE or CE diameter) consequently leads to oversimplifications.

Not only size, but shape parameters of particles hold vital information on sedimentary transport and deposition mechanisms and post-depositional, environment-related alterations. As the terms particle morphology, form and shape have been used in a variety of ways in published papers, here, particle shape includes relative dimensions of particles, overall smoothness of particle outline and roughness. Traditional image analysis techniques have been applied widely, however previously published studies have been carried out on populations with much smaller number of particles compared to automated analyses. Measurement of particle shape is time-consuming. Automated static image analysis is still uncommon and underexploited for particle size and shape distribution analysis of sediments. The use of automated digital image analysis solves the issues generated by low number of measured particles as it is more precise, less time-consuming and easier to use compared with traditional methods. The average particle number of automated imaging amounts to ca. 10^4-10^6 particles, which allows us to gain statistically robust and objective insights into the morphological characteristics of particles. Various size and shape parameters, as well as optical intensity values of each particle, are routinely measured and number-size distributions can easily be converted to volumetric distributions, thus the direct comparison with results obtained by laser diffraction can be done. To date, only a few studies have been published on automated image analyses of particle size and particle shape parameters of sedimentary deposits, and therefore much uncertainty exists about the relationship between the different methods.

Methodology

Granulometric data and Raman spectra were obtained from automatic static image analysis of Malvern Morphologi G3-ID (Malvern Instruments Ltd., UK), which is an advanced particle characterization apparatus. This device allows thousands of particle shapes to be quantified in a few hours and it has recently been used for quality control in the pharmaceutical and mining industry. Nevertheless, only a few studies have exploited image-based methods in sedimentology so far, apart from preliminary studies designed to demonstrate its potential.

Generally, ~7 mm3 of sedimentary particles were dispersed onto a flat glass slide with an instantaneous (10 ms) pulse of 4 bar compressed air and 60 s settling time. Particle imaging was conducted using the 20× magnification lens (960× magnification, 40 pixel per µm2 resolution) of the Morphologi G3-ID device and z-stacking was enabled (two layers above and below the focal plane, equivalent to 27.5 μm in total).

Generally, ~7 mm3 of sedimentary particles were dispersed onto a flat glass slide with an instantaneous (10 ms) pulse of 4 bar compressed air and 60 s settling time. Particle imaging was conducted using the 20× magnification lens (960× magnification, 40 pixel per µm2 resolution) of the Morphologi G3-ID device and z-stacking was enabled (two layers above and below the focal plane, equivalent to 27.5 μm in total).

Size and shape parameters of ~250,000 individual particles were automatically recorded by the software of the Mavern Morphologi G3-ID device for each sample from the captured high-resolution grayscale images. The most important granulometric parameter of the image analysis based grain size measurements is the circle-equivalent (CE) diameter of the non-spherical, irregular-shaped particles. This parameter is calculated as the diameter of a circle with the same area as the projected two-dimensional particle image. The number-based grain size distribution is calculated in MATLAB (version R2016a) by classification of every particle into logarithmically-spaced size classes. Default size-bin allocation of Malvern Mastersizer was chosen to these calculations to make the comparison of image analyses and laser diffraction results more accurate and representative; particle size data are classified into 101 logarithmically spaced size-bins in the range between 0.01 and 3000 µm (the central value of the ith size-bin = 0.0081e0.128i, where i=1:101).

For transforming number-based distributions into volume-based distributions CE diameter is used for the calculation of particles volume (sphere-equivalent [SE] volume) as a weighting factor. The volume of a given size bin is specified by weighting with the total SE volume of particles classed into this size range.

Length and width are estimated from major and minor axes of the particles (Malvern Instruments Ltd., 2015). The major axis is calculated as a line through the centre of mass of the two-dimensional projected image at an orientation corresponding to the minimum rotational energy of the shape. The major axis parameter is the angle of the major axis from a horizontal line, while the minor axis passes through at a right angle to the major axis. All perimeter points of the object are projected onto the major axis (minor axis), and the longest distance between the points is the length (width) of the particle. Other simple grain size parameters as particle area or perimeter can easily be determined using the acquired images.

Grain shape parameters provide additionally information apart from size. Aspect ratio is the ratio of width and length, while elongation is 1-aspect ratio. The circularity parameter of a particle describes the proportional relationship between the circumference of a circle equal to the object’s projected area and perimeter. Convexity and solidity are determined using the convex hull (theoretical rubber band wrapped around the particle) of the two-dimensional images. Convexity is the ratio of perimeter of the convex hull to the particle perimeter, while solidity is the ratio of the particle and convex hull areas; these are parameters of the particle edge roughness.

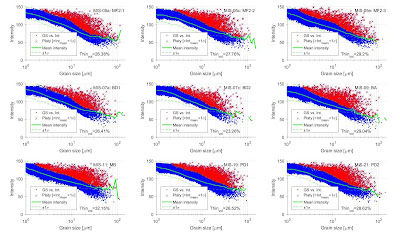

Simultaneously, the mean grayscale intensity and standard deviation of particles were also measured as the bottom light (diascopic) illumination transmits through the particles. White light intensity of each pixel of particles is recorded on an 8-bit (28) scale from 0 to 255, where intensity value of zero is white, 255 is black. The automatically recorded dimensionless values serve as a proxy of optical properties. Mean intensity values are dependent on chemical composition, mineralogy and particle thickness, while standard deviations of intensities are controlled by the heterogeneity of particle constitution and surface morphology.

Chemical analysis was performed using the built-in Raman spectrometer of the Malvern Morphologi G3-ID. Spectra were acquired from several hundreds of targeted individual particles. These were compared with library spectra (BioRad-KnowItAll Informatics System 2017, Raman ID Expert) and correlation calculations were performed to determine the mineralogy of the targeted sedimentary grains.

Image analysis-based measurements were organized into a number-based database. All of the particles have their own identity number (ID) being the primary key in the data matrix. Each row represents one particle and columns of the table are size and shape parameters. Large numbers of measured particles ensure a statistically robust and objective insight into the granulometric characteristics of the investigated samples.

Filtering out stacked

particles and aggregates

Sometimes

it can be noticed that particles are not individual grains, but are clumps

of particles by natural aggregation of single grains or by artificial stacking

of particles during dispersion onto the glass slide. Using the appropriate

shape parameters, these compound objects can be filtered out. Irregularly

aggregated particles often cannot be excluded using only one parameter. This is

why previous studies also applied combinations of intensity and convexity; circularity and convexity,

solidity and convexity to distinguish aggregated particles.

As these previous papers were dealing with microcrystalline cellulose and

volcanic ash, morphologically significantly different material than granular

particles of paleosols of aeolian dust-derived loess series, in this study, we

applied a new combination of parameters to filter out stacked particles using elongation

(or its complementary, the aspect ratio) and circularity thresholds together. Captured

two-dimensional images of aggregated particles revealed that the perimeters of

these rougher objects are larger than that of individual grains with similar

CE-diameter. This observation formed the basis of application of convexity

values in previous studies . However, perimeters of two-dimensional projections of elongated

particles can also be significantly higher than those of solid ones due to

circumferential pixels, so particles with low [<0.4] elongation (high

[>0.4] aspect ratio) and low circularity [<0.45] form a class

representing stacked or aggregated grains.

Sufficient number

of measured particles

Experiences

with automated static image analysis by Malvern Morphologi G3-ID indicate that

scanning of ~7 mm3 of (silt- and fine sand-sized) sedimentary samples on circular, 60 mm

diameter areas of glass slides provide shape and size parameter information on

~1-1.5 million particles. Since measurements are time-consuming (average 6-hour

measurement time per sample), the generated data-file sizes are large and

impractical, and for cost- and energy-efficiency reasons it seems important to

determine the particle number sufficient for a statistically representative

granulometric characterization. The large number of acquired grain images and

obtained parameter data allowed us to perform a subsampling experiment. Clusters

with different numbers of randomly selected particles were sub-sampled from a

total of 1 million measured grains. Every sub-sample clusters include the

results of 100-step iterations of random particle selections.

Underestimation of the finest fractions by image analysis: a theoretical approach

Underestimation of the finest fractions by image analysis: a theoretical approach

The

measured CE diameter in image analysis is calculated from the two-dimensional

images of particles. It is generally assumed that the instantaneous pulse of

compressed air disperses the sedimentary particles onto the glass slide with a

consistent orientation with their largest area facing to camera. However, this

is only one outcome out of infinite possible projections of a three-dimensional

object. During measurements made by dynamic image analysis techniques these

kinds of particle orientation problems do not distort the results since freely

falling particles can rotate freely in all directions.

To demonstrate and quantify this distortion, we modelled the deformation of two-dimensional projected areas of randomly rotated, simple, theoretical three-dimensional geometric solids. Shape parameters of the solids were quantified based on the edge-ratios, where x is the longest edge and x>y>z. Platyness (z/y) and aspect ratios (y/x) were chosen from 0.1 to 1, while the volume of the solids was kept constant at 1 µm3.

To demonstrate and quantify this distortion, we modelled the deformation of two-dimensional projected areas of randomly rotated, simple, theoretical three-dimensional geometric solids. Shape parameters of the solids were quantified based on the edge-ratios, where x is the longest edge and x>y>z. Platyness (z/y) and aspect ratios (y/x) were chosen from 0.1 to 1, while the volume of the solids was kept constant at 1 µm3.

The

XY-plane projected areas are dependent on two major factors: (1) rotation

angles (αx; αy); and (2) shape parameters (edge-ratios)

of the objects. To determine the effect of rotation angles on projected areas,

the αx and αy angles were modified from 0° to 179° and

the projected areas were calculated for every rotation angle-pairs. The mean

value of the rotation-dependent XY-plane projected areas is regarded as the

orientation-averaged projected area representing randomly oriented object.

The introduced CErot ratio is the quotient of the largest face area-based CE diameter (it is assumed during the image analysis that this arbitrary orientation is set) and orientation-averaged projected area-based CE diameter (the projected area of a randomly oriented particle). Larger than 1 CErot ratio values denote that the image analysis-based measurement overestimates particle size, while ratios <1 imply underestimation. These CErot ratios were calculated for every possible aspect ratio-platyness combinations. The displayed surface shows the level of overestimation as a function of shape parameters (orientation-averaged projected area). The higher the anisotropy of particles is, the higher the chance of overestimation of image analysis-based grain size measurement is.

The introduced CErot ratio is the quotient of the largest face area-based CE diameter (it is assumed during the image analysis that this arbitrary orientation is set) and orientation-averaged projected area-based CE diameter (the projected area of a randomly oriented particle). Larger than 1 CErot ratio values denote that the image analysis-based measurement overestimates particle size, while ratios <1 imply underestimation. These CErot ratios were calculated for every possible aspect ratio-platyness combinations. The displayed surface shows the level of overestimation as a function of shape parameters (orientation-averaged projected area). The higher the anisotropy of particles is, the higher the chance of overestimation of image analysis-based grain size measurement is.

Volume-based

distribution curves were derived from the number-based database by weighting

the individual particles with their sphere-equivalent volume, this assumption

of spherical shape leads to further distortion of the results. Another

correcting factor, the so-called CE/SE ratio was also introduced to reduce this

inaccuracy of exchange transformation from number- to volume-based distribution

functions, where SE diameters are equal for all modelled objects (as the volume

of all these solids were defined as 1 µm3). Similarly to CErot

ratios, CE/SE ratios were specified for every possible aspect ratio-platyness

combinations,

so mathematical relationships among the shape and rotation determined factors

and aspect ratio-platyness values were assessed.

Aspect

ratio of every single particle is known, which allowed us to get a more

accurate 2-dimensional representation of 3-dimensional particles, only the

particle thickness need to be estimated and the CErot and CE/SE

correction factors can be determined for every investigated particles.

Assessment of the

3rd dimension of particles: intensity based thickness assessment

As a direct consequence of the previously discussed

uncertainties, the major drawback of static automated image analysis is the

unknown thickness of particles. To get an approximate estimation of the

third-dimension, mean intensity values of the captured grayscale images were

analysed in a completely novel way. Light transmission of sedimentary particles

is influenced by thickness beyond mineral composition and colour. For this

intensity based thickness estimation method, average intensity values for all

(n=101) grain size classes were determined and particles with an intensity being

larger than the sum of their class intensity mean and standard deviation [Intparticle-IDi > mean(IntGSbin-jth) + σ(IntGSbin-jth), where Intparticle-IDi is the intensity of ith particles from the jth size class, mean(IntGSbin-jth) and σ(IntGSbin-jth) are the average and standard

deviation of the size class j] were

classified as thinner (or flatter) than average (‘platy’) particles. Later this

classification of platy and more spherical particles was used during the

mathematical adjustment with different assumptions for the 3rd dimension

anisotropy (z/y: normal distribution for more spherical grains; z/y<0.1 for

platy).

As a direct consequence of the previously discussed

uncertainties, the major drawback of static automated image analysis is the

unknown thickness of particles. To get an approximate estimation of the

third-dimension, mean intensity values of the captured grayscale images were

analysed in a completely novel way. Light transmission of sedimentary particles

is influenced by thickness beyond mineral composition and colour. For this

intensity based thickness estimation method, average intensity values for all

(n=101) grain size classes were determined and particles with an intensity being

larger than the sum of their class intensity mean and standard deviation [Intparticle-IDi > mean(IntGSbin-jth) + σ(IntGSbin-jth), where Intparticle-IDi is the intensity of ith particles from the jth size class, mean(IntGSbin-jth) and σ(IntGSbin-jth) are the average and standard

deviation of the size class j] were

classified as thinner (or flatter) than average (‘platy’) particles. Later this

classification of platy and more spherical particles was used during the

mathematical adjustment with different assumptions for the 3rd dimension

anisotropy (z/y: normal distribution for more spherical grains; z/y<0.1 for

platy).

No comments:

Post a Comment